Reliable customer delivery times, reduced stress: DELMIA Ortems planning solution appeals to Mitsubishi Chemical Performance Polymers

Industry of the Future: A Practical Guide – Getting Started

It’s behind us when SMEs and ETIs used to say “digital is expensive and I don’t see what it’s for”. Today, a majority of entrepreneurs are aware of the usefulness of modernising their industrial facilities. On the other hand, when it comes to taking action and initiating a transformation project, certain apprehensions surface. “Complicated”, “not the time”, “not the means”, “not the staff”… How to help SMEs – ETI to overcome these obstacles to enable them to develop their factory?

Industry of the Future: Practical guide – How I commit my employees

Setting up technological tools to produce is essential in the context of a digital transformation project. However, this is not enough to guarantee the success of such a project. Indeed, a successful digital transformation requires the commitment of employees to the project.

Industry of the Future: A Practical Guide – Where to Start?

If today manufacturers have understood that it is becoming essential to integrate digital tools to improve their productivity and competitiveness, it is important to be supported to build a coherent approach.

Industry of the Future: Focus on DELMIA, software solution for the digital factory

DELMIA allows you to model and design the means of production of your plant

The Factory of the Future, for what needs? Machining & digital continuity

The design and machining software are connected, so there is no need to redo the work if the design office is modified. The programming of the machine tool is recalculated according to the changes. This considerably reduces the time between design and machining.

The Factory of the Future, for what needs? Simulation, digital twin, MES, MOS and IoT

Today, manufacturers are seeking operational excellence, greater flexibility and part of a continuous improvement process. In a context of digital continuity, it is fundamental to meet these challenges, to provide the right information to the right person, at the right time, to make the right decision.

The Factory of the Future, for what needs? Additive Manufacturing & 3D Printing

With direct additive manufacturing, we are witnessing a revolution in the sense that we are totally changing the way we think and design. For the first time, we no longer reason in process limitation but from the possibilities and functionalities that we wish to give to the part.

The Factory of the Future, for what needs? Robotics, Simulation & Virtual Factory

The factory of the future, digital factory, digital factory, or factory 4.0… the terms are numerous to speak of modernization of the industrial tool. These evolutions are made possible thanks to new key technologies such as IoT, big data, artificial intelligence, or augmented reality.

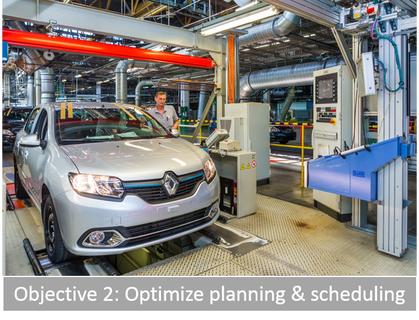

The Factory of the Future, for what needs? Planning & scheduling

The employee will be able to make better trade-offs, using a scheduling and decision support tool. As soon as a customer order arrives, the software solution will allow the best planning of the means (machines and human resources). The manufacturing instructions will be sent in real time to the operators.

The Factory of the Future, for what needs? Collaborative platform and digital continuity

And at the same time, tomorrow’s plant is much more than technology. It is a different way of organizing work to optimize its production process and anticipate hazards. So technology is a tool, but what key organizational needs does it address?

The Factory of the Future: what’s at stake?

Indeed, man is a central element of the factory of the future and an integral part of the company’s value chain. Digital transformation will therefore make it possible to work more comfortably and efficiently by optimizing workstations so that physical robotization combined with process automation allow better decision-making and increased agility to solve problems effectively.

KEONYS expertise at the service of the industry of the future

Our mission is to accompany the modernization of the industry thanks to our expertise in the integration of digital solutions.

From start-ups to large groups, our ambition is to rethink and implement new industrial processes to build together a sustainable, humane and efficient economic model.

Bilsing Automation Testimonial – Reduce machine set-up times

Bilsing Automation was originally a company specialized in the manufacture and sale of grippers for industry, a tool for handling body panels before assembling them Since the deployment of a digital simulation solution, the core business has focused on…

ARC Testimonial – Multi-site collaboration

At ARC glass design begins in France, continues in China and ends in the United Arab Emirates. The challenge for ARC was to deploy a collaborative work platform for its production sites located in four countries (United States, China, United…

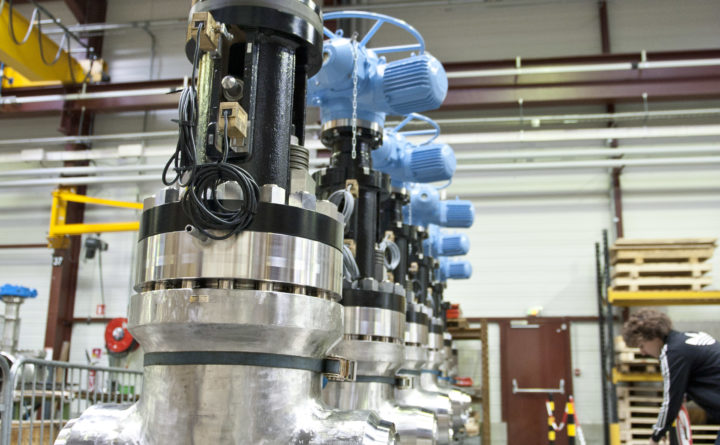

VELAN Testimonial – Planning production in a highly challenging environment

In a context of electro-nuclear development, China wishes to launch a programme to build 40 reactors over 25 years. Velan is then chosen to supply the fitting In order to meet this demand, Velan is forced to increase its…